DISCONTINUED products + substitutions

That was a good one, but it isn't available anymore

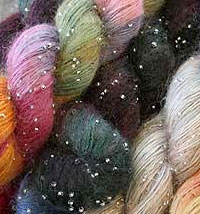

Sadly, some of our favorite yarns (and bags, needles) are not being made anymore, but the good news is we are always finding more great new fabulous yarns! If you've arrived here it means your choice is discontinued and not available. For a great substitution for your pattern, choose from yarn types below, where you can then choose a new yarn by weight etc. Need help? Just click chat balloon below!

See also knitting bags + knitting patterns + knitting needles

YARN SUBSTITUTIONS: CHOOSE BY FIBER

Here at Fab you can find the best yarns by brand, by fiber or by weight, either from our main yarn page or from the handy pop-up menus at the top of the left (nav bar) column.

If you got here looking for patterns for a discontinued yarn see our main patterns page as we may still have them! Or just ask for help and we can get you knitting again!

If you're looking for the best in knitting bags, knitting needles, knitting gifts or anything else relating to knitting and crochet, you've come to the right place! See why knitters call us "the best yarn store online!"

Need help?

If you need help just click the chat button on your screen, or EMAIL US and we'll help you find what you're looking for! Again sorry for the inconvenience--here at Fab we pride ourselves on taking that extra step to make it easier for you to get what you want!

—xxx Fab